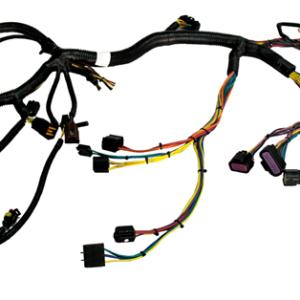

Wire harness factory explains the problems that need to be paid attention to when replacing automobile wiring harness!

With the development of science and technology, more and more wire harness factories produce high-tech products, which are used in our days. For example, wire harness detectors, if there are shortcomings in the more complex car wire harness circuits, it is difficult to find out where the shortcomings are by manual discrimination. If the car wiring harness detector is used, these problems can be handled well. The following is an introduction to the replacement of car wiring harness.Assembly replacement of car wiring harness:

I. Visual Inspection

1. The type of the new car wiring harness should be the same as the type of the original model. The wire terminal and the wire are firmly connected. You can pull each connector and wire by hand for loosening or falling off.

2. Compare the new car wiring harness with the original car wiring harness, such as: the standard of car wiring harness, wire terminal connector, wire color, etc. should be fundamentally common. If there is any doubt, the wire harness detector can be used to test and admit that the car wire harness is in good condition before it can be replaced in the future.

Second, car wiring harness installation

Three, line inspection and connection experiment

The connectors, plugs and sockets of each car equipment must correspond to the sockets and plugs on the car wiring harness. After each connecting wire is connected with electrical equipment, a certain margin should be left. The wire should not be pulled too tightly or put too loosely.

1. Check the wiring

After the replacement of the car wiring harness, the first requirement is to check whether the connection between the car wiring harness connector and the electrical equipment is correct, and whether the positive and negative electrodes of the battery are correctly connected.

The grounding wire of the battery can be temporarily disconnected, and a 12V, 20w bulb is used as a test lamp, and the test lamp is connected in series between the negative electrode of the battery and the grounding end of the frame, close all electrical equipment switches on the vehicle. The test lamp should not light up normally, otherwise it is indicated that the circuit has defects. When the circuit is normal, remove the bulb, use a fuse with a capacity of 30A, and connect it in series between the negative electrode of the battery and the ground end of the frame, do not start the engine, and turn on the power supply of each electrical equipment on the car one by one, check the electrical equipment and wiring, after admitting that the electrical equipment and wiring have no defects, remove the fuse and connect the battery ground wire.

The replacement of car wiring harness is introduced in detail by the wiring harness detector factory. We can use these methods to check the car wiring harness when replacing the car wiring harness in the future.

English

English 中文

中文